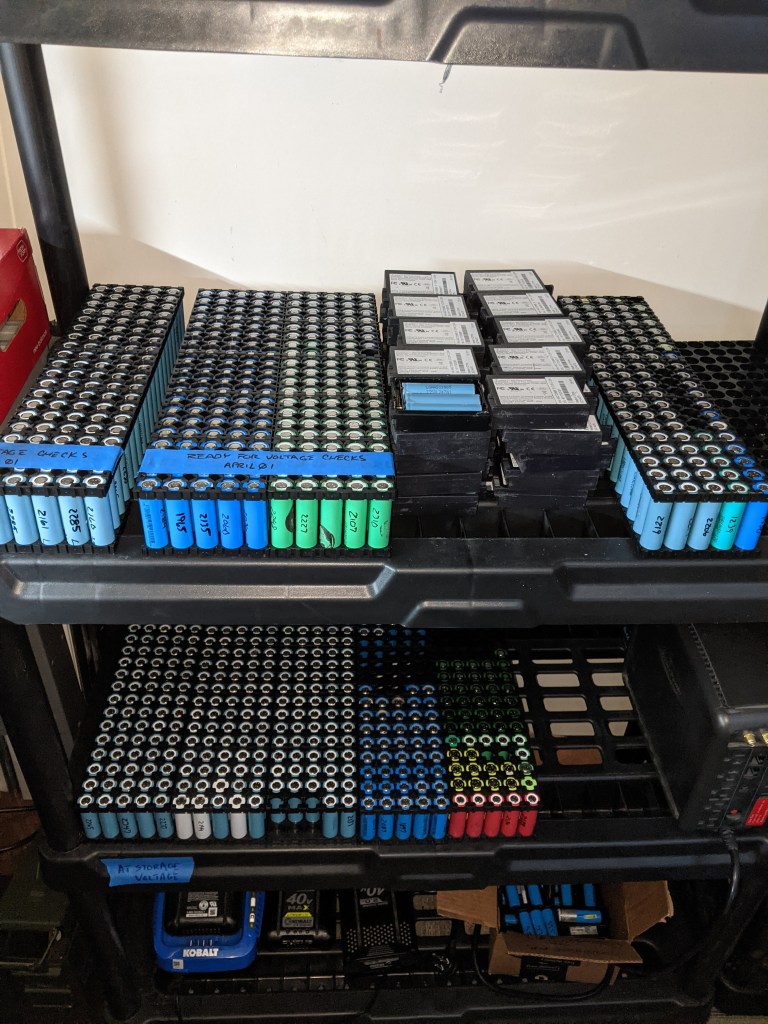

Battery Shucking Progress

The next batch to get us over the 1000 cell count.

Many have come in with good capacity left, a LOT above 2200 mAh, and now they’re just waiting their 30 days to see if we have any self-dischargers, or “leakers”.

How do you test a cell’s capacity and identify the “keepers” and the “leakers”? These 3.7v nominal cells are charged with specific charging equipment (more on them later) to 4.2v, discharged to check their capacity, and then recharged to 4.2v and left for 30 days. If, after 30 days, their voltage has fallen below 4.1v then they have something in them internally that will drain their capacity just sitting there.

Lastly, we discharge the keepers down to a good storage voltage for safety and to preserve the cell’s life span.

InSoFast the North Wall

After cutting and dry-fitting add some expanding Gaps & Cracks Polyurethane Foam Sealant and a generous amount of adhesive to the back of each CX-44 panel. Slide in place and apply pressure to spread the adhesive evenly.

Most Crack Sealant will do, but we like the Great Stuff Pro. Don’t use the throw away handle and nozzle that it comes with. Get a metal nozzle with gun grip handle. You may have to scrape off the tip with a knife but your bottle will last up to a month if kept in a cool place.

The most common pitfall to watch out for is the panel shifting too far left or right which will cause the opposite facing corrugated angle to be too far from the CX-44 panel. And if it’s too far the glue won’t make contact. To avoid this problem check for a good fit left and right when dry-fitting. If the previous panel is “pushing” your next panel down the row and causing an offset, you may have to shave a little off the tongue and grove to shift it a little to the right. It doesn’t have to be perfect. It just needs to be evenly placed to give as much chance for the adhesive on the panel to make contact with the wall.

The numbering system we chose to use was N or S (North or South Wall), Row Number, then a Hexidecimal final digit (0 to F) for the count of panels from the back of the container towards the doors. Why HEX? Because when you have a 40 foot container and you get to number 9 (N29), you can’t just put a ’10’ on the end (like N210), I found it easier to just continue with a single digit solution like they did when inventing Hexidecimal. N2A would follow N29.

We finished the North rows 1 and 2 so that we could continue the back wall up another row and around the window. By the time the back wall was up, the North wall was dry and could take Row 3.

Starting Row 3

North Wall done up to Row 4 and down to the Kitchen Window location. Guess what we’re doing next month?

See y’all next month when we cut out the window for above the kitchen sink and continue the InSoFast all the way down the length of the North wall.